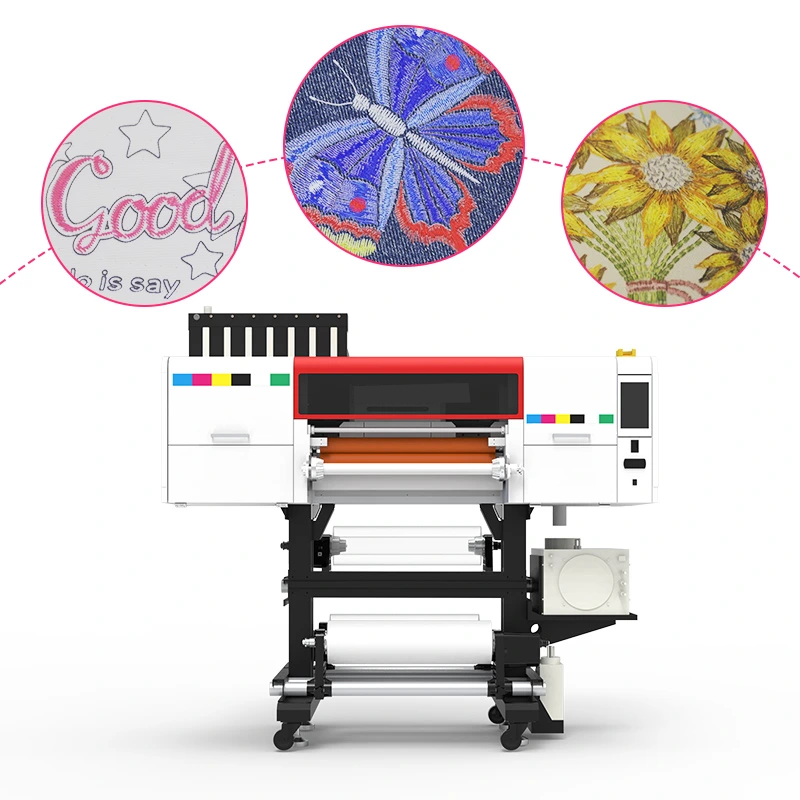

What is UV DTF technology?

UV DTF (UltraViolet Direct to Film) technology is a printing method in which the desired design is printed on special film using UV inks, which are simultaneously cured with a UV lamp, and then transferred to the application surface (object or fabric) with the help of transfer film (and a heat press when needed). More specifically, the process, in simple steps, includes:

- Printing the design on film (A-film) with UV inks

- Immediate curing of the design using UV light

- Lamination with auxiliary (adhesive) film (B-film)

- Transfer of the design onto an object or fabric

The technology functions as a high-durability and high-precision transfer method, without loss of detail.